Reflow Oven

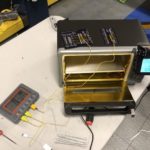

Reflow oven completed, calibrated, and ready for a board.

I did the ‘learn’ cycle which helps the software determine the PID constants for all three heating elements, as well as judging how well you built the oven.

Heat leakage is very small, and at 400F internal temp the outside skin was only 85-96F.

I ran several test ‘reflow’ cycles using the leaded 225F profile, and the graph below shows the performance using both the controller’s thermocouple, plus two thermocouples attached to PCBs in the oven.

The PCBs (and the tray) have much more thermal mass so you can see the lag as the soak cycle starts up, but the overall curve is great, and the PCB gets right to the programmed peak temperature.

The Orange vs Green represent the sensor at the center vs the very edge. These kind of ovens sometimes have problems with reflowing boards at the edge while not cooking board at the center. The difference between the two is about 5 degrees C, which is well within the reflow temperature region.

Next up I’ll paste some boards, install some parts, and reflow.