EZ30

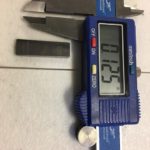

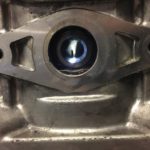

For those of you thinking you just have to see a 10 min video on measuring stuff… Here is a video I made of how I am measuring the clearance for the rod to crank bearing surface in the EZ30R. I am by no means an expert, so feel free to correct me if something I am doing something wrong.

Being an engineer, I used this technique 4 times on the same rod and crank bearing on 4 different occasions just to make sure the method was somewhat consistent. The results were surprisingly good, all being within 1/10,000ths of an inch.

The factory (non turbocharged variety) clearance spec is .0009″ to .0020″, however with the motor built in turbocharged form most builders would try to be in the .0015″ to .0025″ range. My other turbocharged EZ30R (currently in my WRX, running since 2008) was built by me with clearances of right around .0020″).